تمرکز ژنلونگ بر تقاضا ، تلاش برای پیگیری نوآوری

جعبه سوئیچ دیواری دفن شده از فولاد ضد زنگ برای شلنگ گاز خانگی

فولاد ضد زنگ در خارج از جعبه سوئیچ دیواری برای شلنگ گاز خانگی

استیل ضدزنگ دریچه توپ داخلی و خارجی با پایه برای شیلنگ گاز خانگی

مواد معمولاً برای لوله کشی گاز داخلی مسکونی شامل لوله های فولادی گالوانیزه ، لوله های استیل ضد زنگ ، لوله های کامپوزیت آلومینیومی پلاستیک و لوله های پلی اتیلن (PE) است. لوله های فولادی گالوانیزه به دلیل خاصیت ضد خوردگی و هزینه متوسط ، به طور گسترده در لوله کشی گاز داخلی مورد استفاده قرار می گیرند ، در حالی که لوله های PE به دلیل مقاومت در برابر خوردگی ، مقاومت در برابر ضربه و مقاومت در برابر آب و هوا ، به تدریج در سالهای اخیر محبوبیت خود را به دست آورده اند.

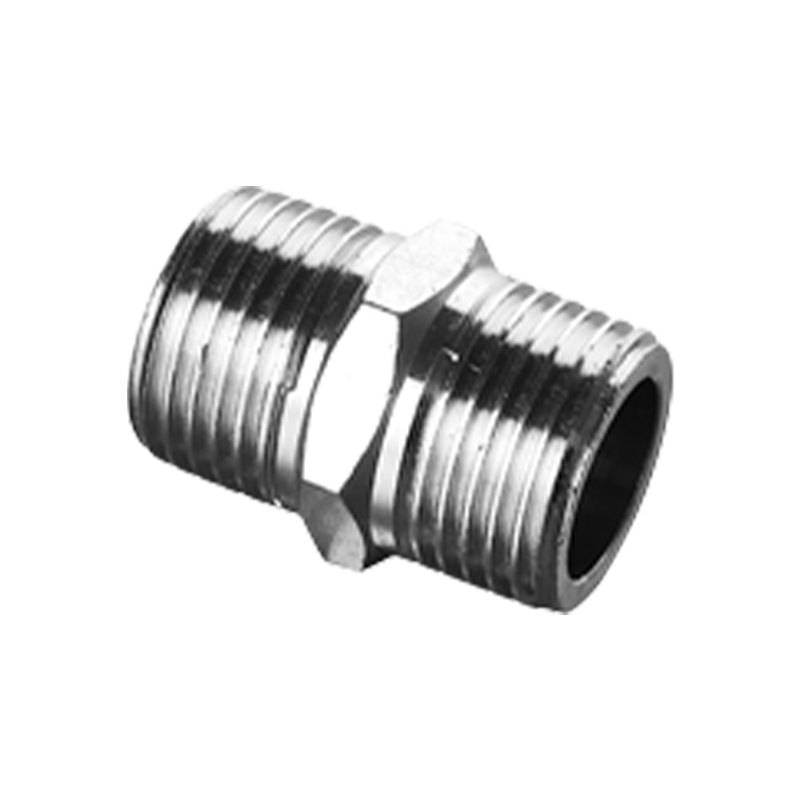

اتصالات لوله برای اتصال خطوط لوله ، از جمله آرنج ، سه تایی ، صلیب ، فلنج ، اتصالات و غیره مهم است. آنها لوله ها را از طریق روش های مختلف اتصال به یک سیستم کامل وصل می کنند. انتخاب اتصالات لوله باید با توجه به عواملی مانند مواد لوله ، مشخصات ، روشهای اتصال و شرایط استفاده مشخص شود. اتصالات مواد و تطبیق لوله ، اتصالات فولادی گالوانیزه مشترک ، اتصالات از جنس استنلس استیل ، اتصالات کامپوزیت آلومینیومی پلاستیک و اتصالات PE و غیره. مشخصات اتصالات لوله با توجه به مشخصات لوله برای اطمینان از سفتی و قابلیت اطمینان اتصال. $ $

کارخانه استاندارد

کارخانه استاندارد

سالهای تأسیس

پوشش مساحت 40 هکتار

منطقه کارخانه

کارمندان شرکت

جوشکاری شکل گیری

In the construction and maintenance of residential gas supply systems, the choice of materials for both pipes and fittings plays a critical role in ensuring safety, durability, and efficiency. The primary materials used for indoor gas piping include galvanized steel pipes, stainless steel pipes, aluminum-plastic composite pipes, and polyethylene (PE) pipes, each with distinct characteristics suited to specific applications. Additionally, the role of pipe fittings in securing and maintaining the integrity of these systems cannot be overstated. This article delves deeper into the types of materials used for gas piping, the selection of fittings, and how these components ensure a safe and efficient gas distribution system.

Galvanized Steel Pipes: Galvanized steel pipes have been a standard choice in gas piping systems for many years due to their inherent corrosion resistance. The galvanization process involves coating the steel with a layer of zinc to protect it from rust and corrosion, which is particularly important in environments where moisture or other corrosive agents are prevalent. These pipes are highly durable and cost-effective, making them a popular choice for residential indoor gas systems. However, galvanized steel is less flexible than other materials and may be more difficult to install in tight spaces.

Stainless Steel Pipes: Stainless steel pipes are favored for their superior corrosion resistance and strength, especially in high-pressure or high-temperature environments. Stainless steel is more resistant to rust and oxidation than galvanized steel, ensuring a longer lifespan in areas where water and humidity are present. Its high tensile strength also makes it suitable for installations where mechanical stress or movement is expected. Although stainless steel is more expensive than galvanized steel, its durability and reliability make it a preferred option for certain residential gas installations.

Polyethylene (PE) Pipes: Polyethylene (PE) pipes are increasingly used in modern gas piping systems due to their lightweight nature, excellent resistance to corrosion, and superior impact strength. PE pipes are also highly flexible, allowing for easier installation, especially in environments with uneven terrain or where bending of the pipe is required. Moreover, PE pipes are resistant to both chemical and environmental factors, such as UV radiation and extreme temperatures, making them ideal for both indoor and outdoor installations. In recent years, the use of PE pipes has become more widespread due to their cost-effectiveness and long-term performance in residential gas distribution.

Aluminum-Plastic Composite Pipes: Aluminum-plastic composite pipes combine the benefits of both metal and plastic materials. These pipes feature an inner layer of polyethylene, an aluminum middle layer for strength, and an outer layer of plastic for additional protection. This combination provides excellent corrosion resistance, flexibility, and strength. Aluminum-plastic composite pipes are particularly useful in residential systems where space constraints, lightweight material needs, or exposure to chemicals are concerns. These pipes are commonly used for indoor gas installations due to their low weight, ease of handling, and resistance to corrosion.

Pipe fittings are essential in ensuring that gas piping systems function properly and maintain their integrity. Fittings are used to connect, control, and modify the direction of the flow of gas within the piping system. Common types of fittings include elbows, tees, crosses, flanges, and joints, which come in a variety of materials to match the type of pipe they are used with.

Material Compatibility: The material of the pipe fitting must be compatible with that of the pipe to avoid corrosion, leakage, or weak connections. For example, galvanized steel pipes should be paired with galvanized steel fittings, while PE pipes require PE fittings. Mismatched materials can lead to system failure, which is why choosing the correct fittings for each specific pipe material is critical to the longevity and safety of the gas system.

Connection Methods: Gas pipe fittings are connected through a variety of methods, each suited to specific materials and application requirements. Common connection techniques include:

Fittings Specifications: The selection of pipe fittings should be based on factors such as the pipe material, diameter, pressure rating, and intended application. Properly sized fittings ensure a secure and reliable connection, preventing leaks and ensuring the overall safety of the gas system. It’s important that the specifications of the fittings match the pipes to maintain the tightness and integrity of the system under various pressures and operational conditions.

Sealing and Pressure Resistance: In residential gas systems, the ability of fittings to create an airtight seal is crucial. High-quality fittings are designed to withstand the pressure exerted by the gas supply and prevent leaks. The material and design of the fittings must be able to endure the pressure and temperature variations that may occur during regular system use. Gaskets, seals, and O-rings are commonly used in fittings to enhance sealing properties and prevent gas leakage.

Zhejiang Zhenlong Energy Equipment Technology Co., Ltd. specializes in manufacturing high-quality gas pipes and fittings for residential, commercial, and industrial applications. With over 30 advanced welding production lines and cutting-edge solid-phase hydrogen furnaces, the company is able to provide a full range of reliable gas pipeline solutions. Our extensive product portfolio includes galvanized steel, stainless steel, PE, and aluminum-plastic composite pipes, as well as a wide selection of compatible fittings designed to meet stringent industry standards.

We adhere to the highest quality standards, certified by ISO9000:2008, and hold the necessary certifications such as the Special Equipment Manufacturing License for Pressure Pipelines issued by the People's Republic of China, as well as the EU CE certification. Our focus on product quality and safety, along with our comprehensive after-sales service, ensures that our clients receive the best solutions for their gas piping needs. Whether it’s for residential, commercial, or industrial applications, Zhenlong’s products provide a safe, efficient, and long-lasting gas distribution system.